As of April 2025, there are 270 active drug shortages in the U.S. healthcare system-a record number. Most of these involve generic drugs, which make up 90% of all prescriptions but only 13% of drug spending. Why does this happen? It's not just about pandemics; the problem runs deeper.

Record Drug Shortages in 2025

The ASHP (American Society of Health-System Pharmacists) reported 270 active shortages as of April 2025. This surpasses the previous record of 323 in Q1 2024. Many of these shortages affect critical medications like antibiotics, chemotherapy drugs, and IV fluids. For example, a 2023 tornado damaged a Pfizer plant, halting production of 15 medications. Similarly, FDA quality issues in India shut down cisplatin production, causing a nationwide shortage of this essential chemotherapy drug.

Why Generic Drugs Are Most Affected

Generic drugs operate on razor-thin profit margins. They account for 90% of prescriptions but only 13% of total drug spending. This economic reality creates vulnerabilities. When drug prices drop, manufacturers may stop producing certain generics because they can't cover costs. Dr. Malta from the USP explains, "There's a clear correlation between drug price and shortage risk, especially for older generics." Some sterile injectables cost less than $5 per unit but require expensive manufacturing processes. This makes them prone to shortages when demand fluctuates or production issues arise.

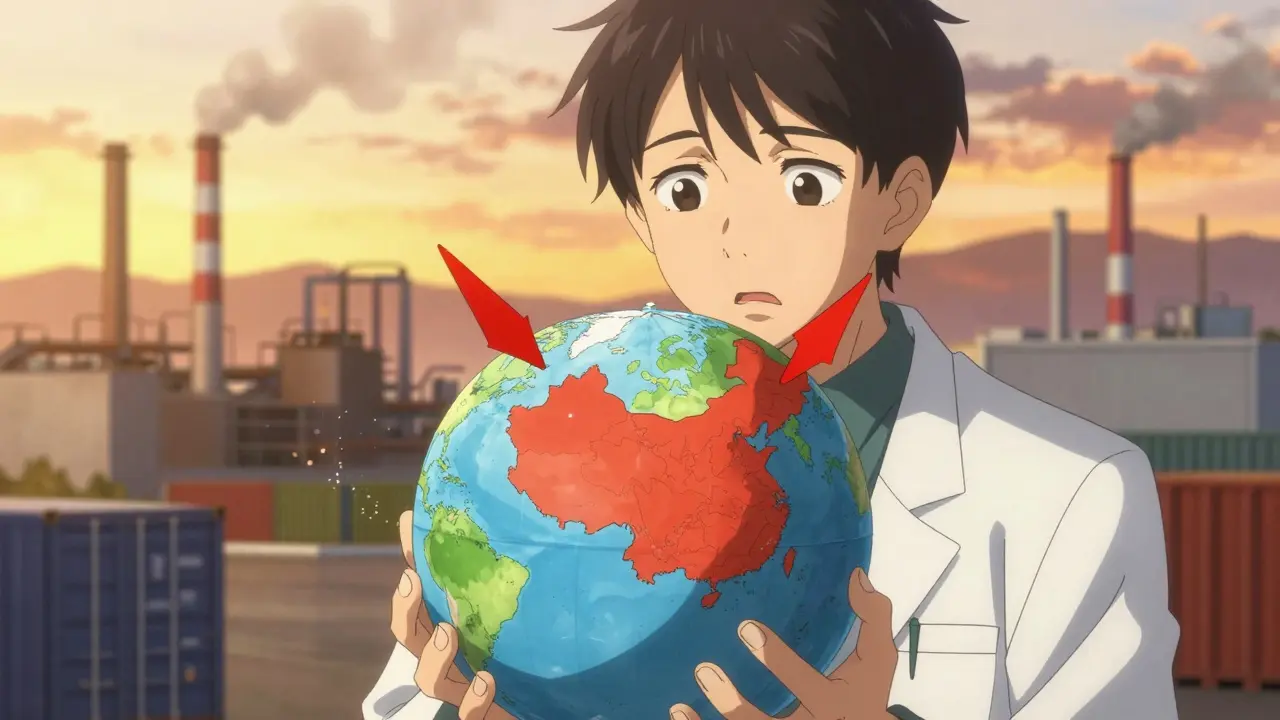

Geographic Concentration of Manufacturing

Less than 30% of APIs (active pharmaceutical ingredients) used in U.S. drugs are made domestically. The rest come from China, India, and Europe. Chinese manufacturers supply about 40% of global API production capacity. However, the FDA has noted "hesitance with sourcing from China because of a history of unreliable manufacturing practices." This concentration creates massive risks. If a natural disaster hits a key facility or political tensions disrupt trade, entire drug supplies can vanish.

Impact on Healthcare and Patients

Drug shortages force hospitals to spend 20-30% of pharmacists' time managing alternatives. Clinicians often have to switch to less effective treatments or delay care. The American Hospital Association states that shortages "force clinicians to make difficult therapeutic substitutions that compromise patient care." Patients face real consequences: delayed cancer treatments, rationed antibiotics, and canceled surgeries. For example, a shortage of heparin-a blood thinner-can lead to life-threatening complications during surgeries.

Brand-Name vs Generic Drug Supply Chains

| Feature | Brand-Name Drugs | Generic Drugs |

|---|---|---|

| Profit Margins | Higher margins allow for investment in supply chain resilience | Thin margins often lead to cost-cutting and fewer backup suppliers |

| Manufacturing Diversification | Global network with multiple suppliers | Concentrated sourcing, often 1-3 manufacturers |

| Inventory Buffers | Large stockpiles to handle disruptions | Minimal inventory due to low profit margins |

| Regulatory Oversight | Strict quality controls during development | Focus on cost efficiency over quality investment |

Solutions and Challenges

Some propose bringing manufacturing back to the U.S., but experts say this isn't feasible soon. Rebuilding domestic capacity would take 5-7 years and $20-30 billion. Instead, solutions include better transparency in API sourcing, expanding the Strategic National Stockpile, and creating mandatory reserves for critical drugs. The Association of Accessible Medicines advocates for policies that ensure sustainable generic drug markets. However, the CSIS analysis warns that "imposing pharmaceutical tariffs could exacerbate these problems by disrupting the existing supply chains," leading to higher costs and more shortages.

Future Outlook

The outlook for drug shortages remains uncertain. Geopolitical tensions could worsen shortages. But collaboration between government, manufacturers, and healthcare providers offers hope. As Dr. Eberle from the University of Wisconsin School of Pharmacy notes, "More manufacturers creating a more predictable supply will definitely help patients." However, without addressing the low pricing issue, shortages will persist. Policymakers are now considering measures like public-private partnerships and transparent labeling for API sourcing, but implementation challenges remain significant.

Why are generic drugs more prone to shortages than brand-name drugs?

Generic drugs face higher shortage risks due to their business model. Unlike brand-name drugs, which have high profit margins and diversified supply chains, generics operate on thin margins. This leads to minimal inventory buffers and concentrated sourcing-often just one or two manufacturers. When a single plant faces issues, there's no backup. For example, many generic sterile injectables are made by only one company. Brand-name manufacturers can absorb costs during disruptions, but generic companies often can't afford to keep production running at a loss.

How do drug shortages affect patient care?

Drug shortages force healthcare providers to use alternative treatments that may be less effective or more expensive. Patients face delayed cancer treatments, rationed antibiotics, and canceled surgeries. For instance, a shortage of chemotherapy drugs like cisplatin can delay life-saving cancer care. Hospitals report increased costs and stress for both staff and patients as they scramble to find substitutes. The American Hospital Association confirms that shortages often lead to compromises in patient care quality.

What role do China and India play in the generic drug supply chain?

China supplies about 40% of global API production capacity, while India is a major manufacturer of finished generic drugs. However, this concentration creates vulnerabilities. Natural disasters, regulatory issues, or geopolitical conflicts in these regions can disrupt entire supply chains. For example, FDA quality issues in India caused a nationwide cisplatin shortage. The U.S. relies heavily on these countries for affordable drugs, but the lack of diversification makes the system fragile.

Why can't the U.S. simply produce all generic drugs domestically?

Rebuilding domestic manufacturing capacity for generic drugs would require 5-7 years and $20-30 billion in investment. The U.S. lacks the skilled workforce and infrastructure for large-scale generic production. Additionally, the low profit margins of generics make it economically unattractive for companies to invest in domestic facilities. Experts agree that onshoring the entire supply chain isn't feasible in the near term and may not be desirable due to higher costs for patients.

What policies are being proposed to address drug shortages?

Current proposals include expanding the Strategic National Stockpile, requiring six-month reserves for critical drugs, and creating public-private partnerships for high-risk generic production. The U.S. Congress is also considering mandatory transparency in API sourcing. However, implementation faces challenges like regulatory hurdles and funding shortages. The Association of Accessible Medicines emphasizes that sustainable solutions must balance economic realities with patient access to essential medications.